ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

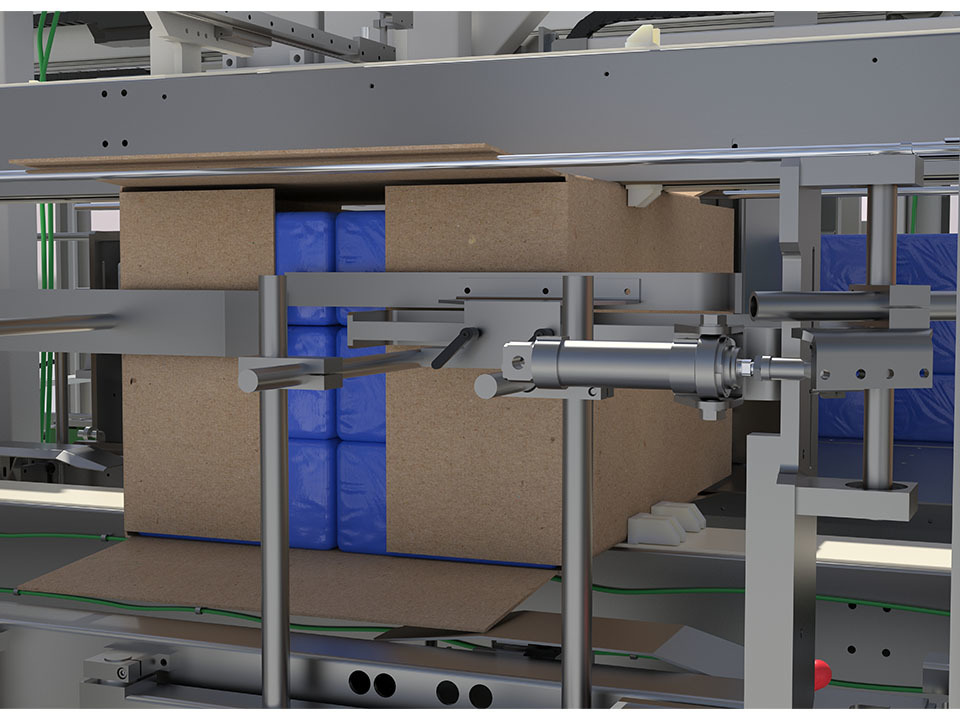

learn moreThrough relocation of flap closers, guides and tuckers throughout the packing station experience a speed increase of 10%.

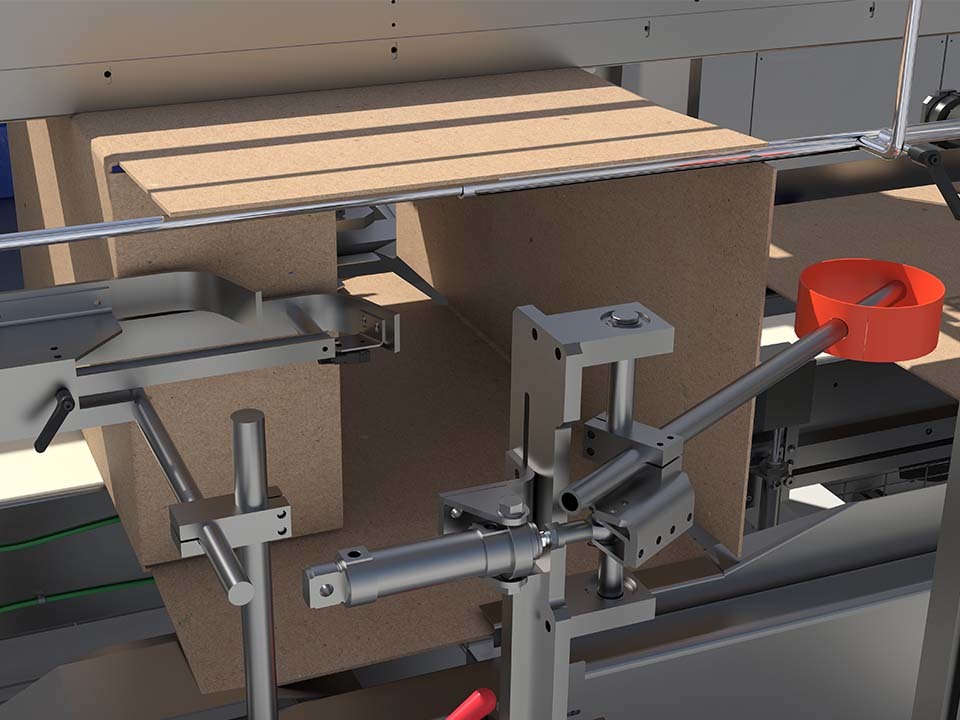

This cost-effective solution of modifying the Forming and Packing stations enables us to increase the throughput of the case packer by moving key functions from the Forming station to the Packing station. These upgrades in the Forming, Packing, and Transition areas of the case packer provide improved case control and faster throughput with only one day required for installation.

Through relocation of leading cleat, tucker station, servo pick and load, and adding a lift station experience a speed increase of 30%.

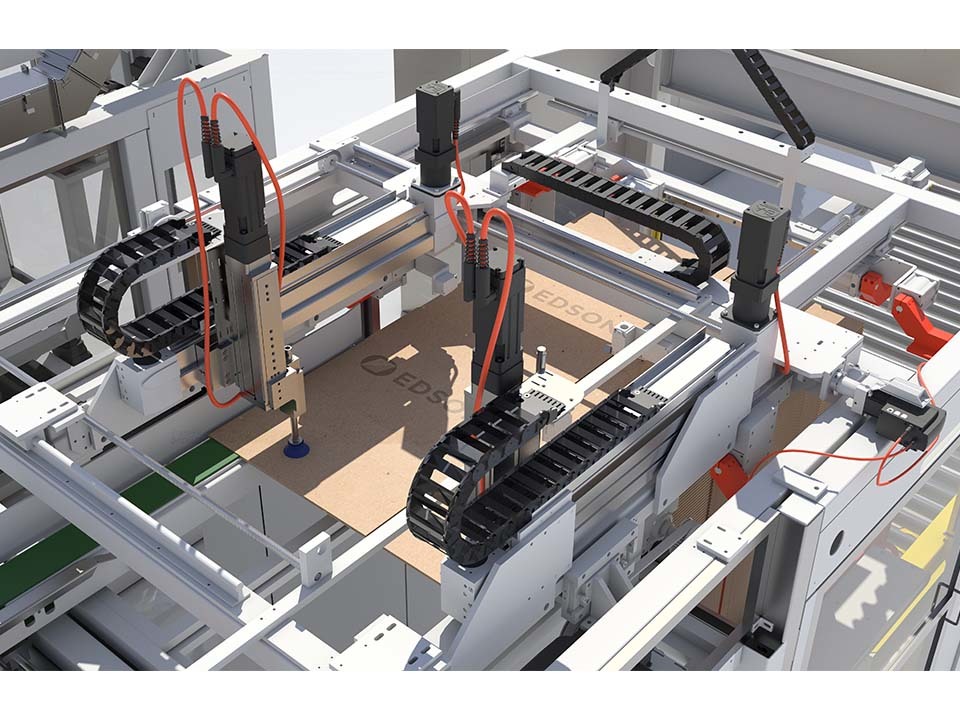

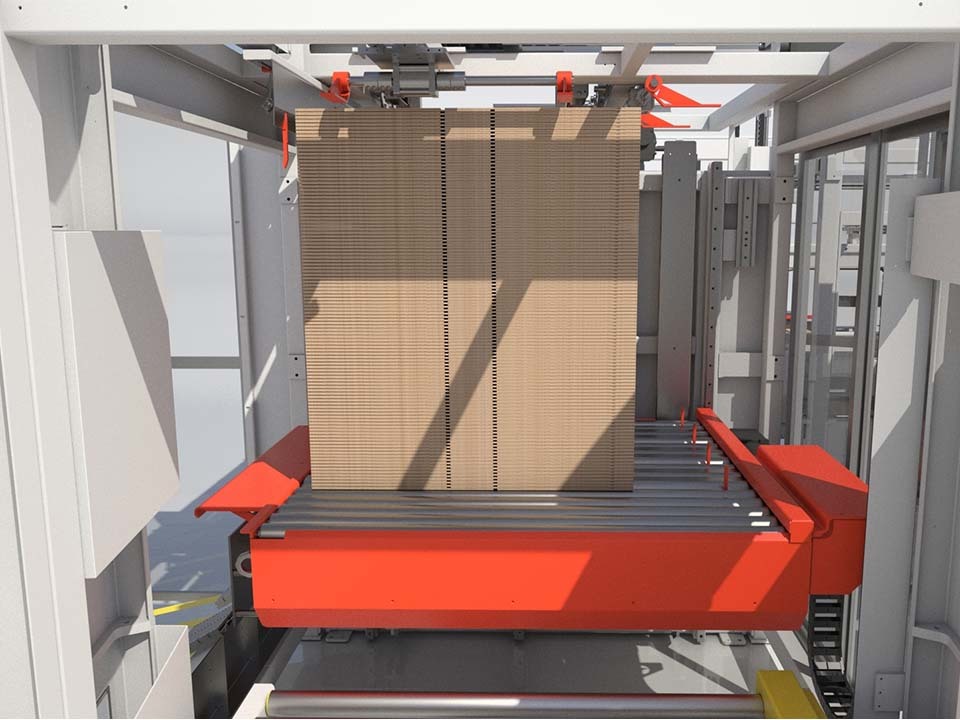

The general layout of the opener sealer component of the case packer consists of five stations which simultaneously perform functions of the case forming, filling, and sealing. Modifications would increase the throughput of the case packer by moving key functions from the Forming station to the Packing station. This includes the addition of a Servo Leading Cleat on the Upper Dispenser assembly to provide stability of the erected case as it indexes through the Opener Sealer stations at elevated speeds. In addition, modifications to the Auxiliary Magazine will provide a continuous supply of KDF’s in the Opener Sealer magazine through high-speed servo control of the Picker and Loader assemblies.